Mesa Services

The leak test is a nondestructive test that allows to check in a production environment the integrity of any part that needs to keep it contents sealed.

The leak test is a nondestructive test that allows to check in a production environment the integrity of any part that needs to keep it contents sealed.

Due to the diversity of individual parts and assemblies made in MESA, it is necessary the use of different equipments and high precision instruments to verify the highest requirements of the inspection and testing codes.

In MESA we use a Continuous Improvement system to ensure the quality of our processes and stay attached to our customers specifications. To achieve this we designed Lean Manufacturing tools and fail-safe processes (Poka-Yoke) to ensure high quality products.

In MESA we use a Continuous Improvement system to ensure the quality of our processes and stay attached to our customers specifications. To achieve this we designed Lean Manufacturing tools and fail-safe processes (Poka-Yoke) to ensure high quality products.

MESA works to be a world class company applying quality systems that allow to achieve continuous improvement and offer products that exceed our costumers expectations.

Kaizen events aim to make immediate changes through a well-organized short duration event. It includes a continuous improvement program based on teamwork and the use of knowledge and skills of the personnel involved, both from the customer and MESA. The principles of Lean Manufacturing are used as well as the various tools and techniques to optimize the operation of previously selected processes.

• Immediate improvements

• Visible, tangible and measurable results

• Customer and Vendor participation

• Documented work standard

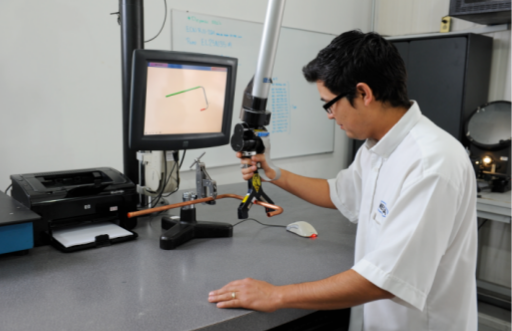

3D Laser Measurement and Audit System

Between the high-precision equipments in MESA to ensure the dimensional quality of its products, is 3D laser measurement machine which is still the hallmark for the measurement and inspection of our products.

Between the high-precision equipments in MESA to ensure the dimensional quality of its products, is 3D laser measurement machine which is still the hallmark for the measurement and inspection of our products.

Más Artículos...

our Services

Manufacturas Especializadas, S.A.

Address

Carretera a Villa de García #3850

Santa Catarina, N.L México 66350

Phone: (52) (81) 8850 2500

Fax. (52) (81) 8338 0141

E-mail: Esta dirección de correo electrónico está protegida contra spambots. Usted necesita tener Javascript activado para poder verla.

CERTIFICATIONS